One-stop Custom Parts Manufacturing Service

CNC Machining Processes

The team at Arktech are highly skilled with experience in the industry of non-standard spare part, specialized in providing customized metal CNC milling turning products processing including Broaching, DRILLING, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM.

Materials: Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys

Surface treatment: Anodized,Brushing,Polishing,Chroming,Plating,Laser engraving,Silk printing

Our wide range of CNC machinery provides our customers with a one stop shop for all of their machined components.

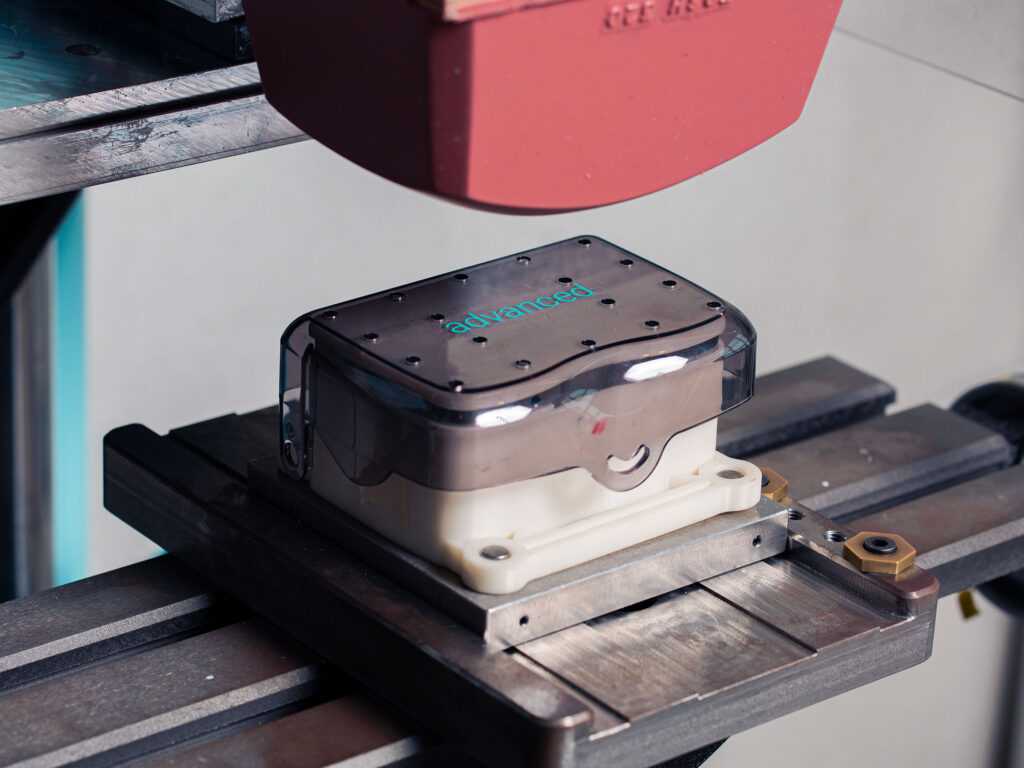

CNC Milling

CNC milling involves removing material from a workpiece using rotating cutting tools. Milling is suitable for producing complex geometries, pockets, slots, and contours.

CNC Turning

In CNC turning, the workpiece rotates while a cutting tool removes material, typically producing cylindrical or symmetrical parts.

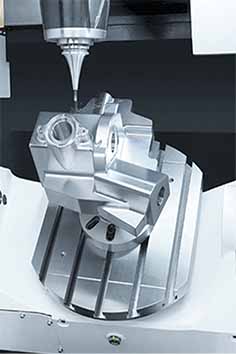

5-Axis CNC Machining

5-axis machining allows for the creation of highly intricate and complex parts that would be difficult or impossible to machine using traditional 3-axis or even 4-axis machines.

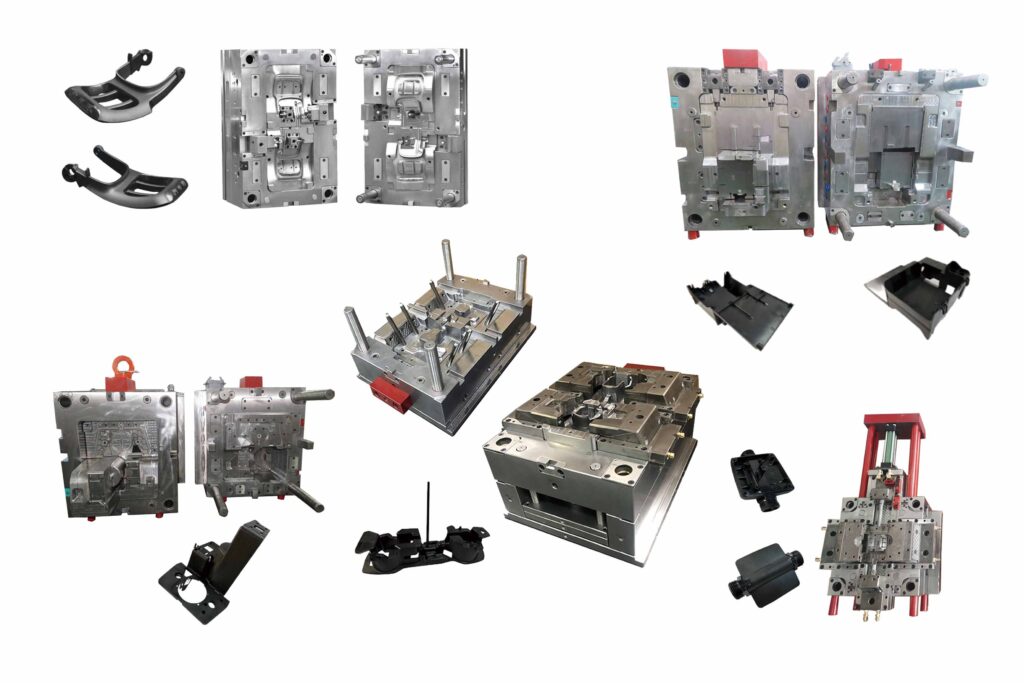

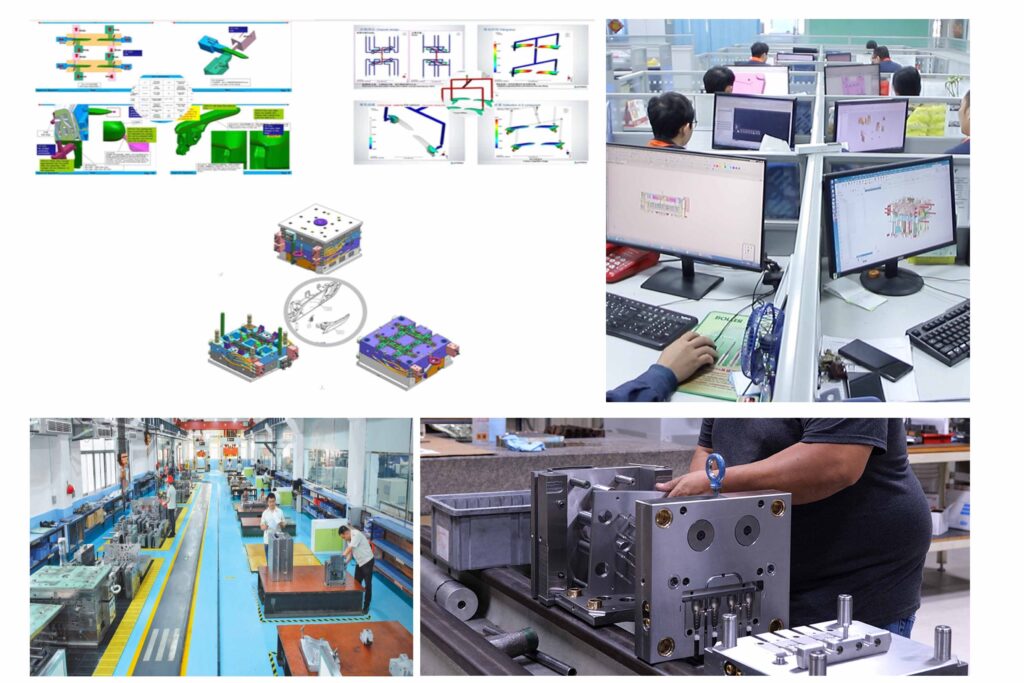

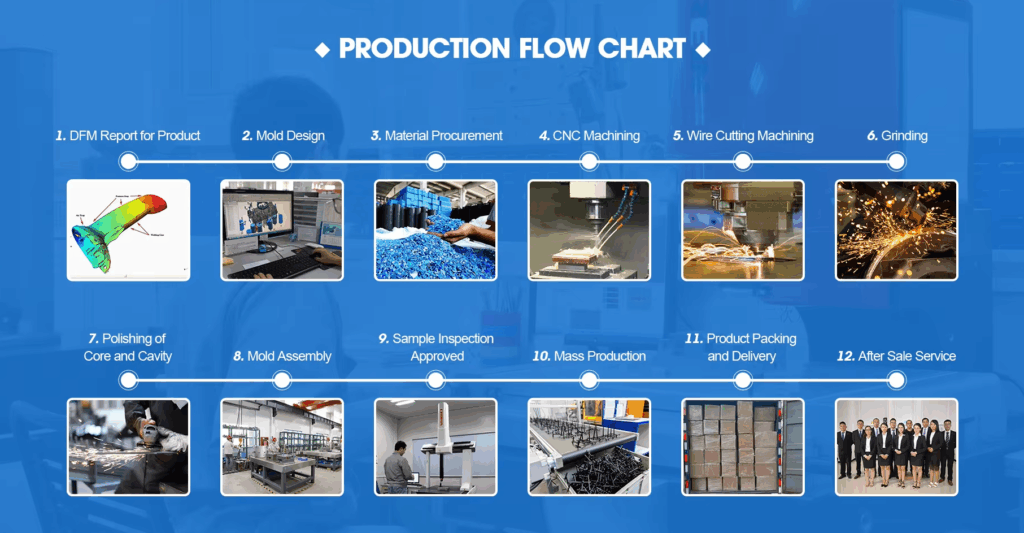

Mold Manufacturing

Arktech Group is one of the most-professional middle-size mold maker withc successfully exported more than 1500 high quality mold. We are familiar with different tooling standard, such as Hasco, DME. Our full service on-site tooling room allow Timesplastics to not only build prototype and production molds for our customers, but also provide for prompt attention to any problem that might arise on production floor. Each of our mold makers has a workstation tied into the network with the lastest CAD/CAM sofeware at their disposal.

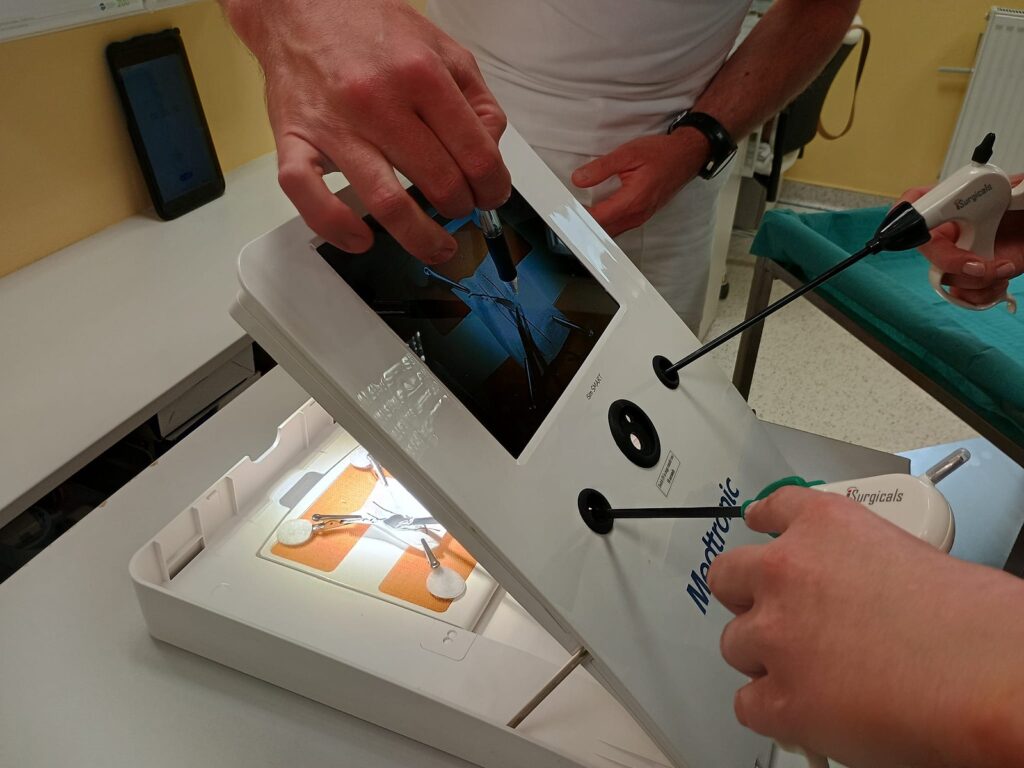

Rapaid Prototype Service

Cast urethane parts are often compared to injection molding materials. For example, a stiff urethane cast part may be described as

“polycarbonate-like,” and a more flexible plastic may be “polypropylene-like.” We group our urethane materials into general categories to help you make quicker decisions and get the best performance on your project. The list below describes the categories of materials and technical examples when selecting polyurethanes.

3D Printing

Rapid Model provides the best rapid prototyping solution in the industry. With the latest industrial 3D printing technology, we can create precise prototypes within 24 hours.

Vacuum casting

Vacuum molding, also known as silicone molding or prototyping, is an economical alternative to small batch injection molding of plastic parts.

Plastic CNC Machining

During prototype or low-volume production, we don’t require molds with plastic machining. This process allows the designers to create parts without molds, unlike other methods.

Plastic Injection Production

Injection moulding at Arktech Group means precision work from less than 2 grams to more than 2.5 kilograms. With a clamping force ranging from 25 to 480 tons, we can offer our customers endless possibilities!

Co-creating also means that we seek cooperation with suppliers of raw materials. That makes Arktech Mold a powerful partner for you in the development of injection-moulded parts!

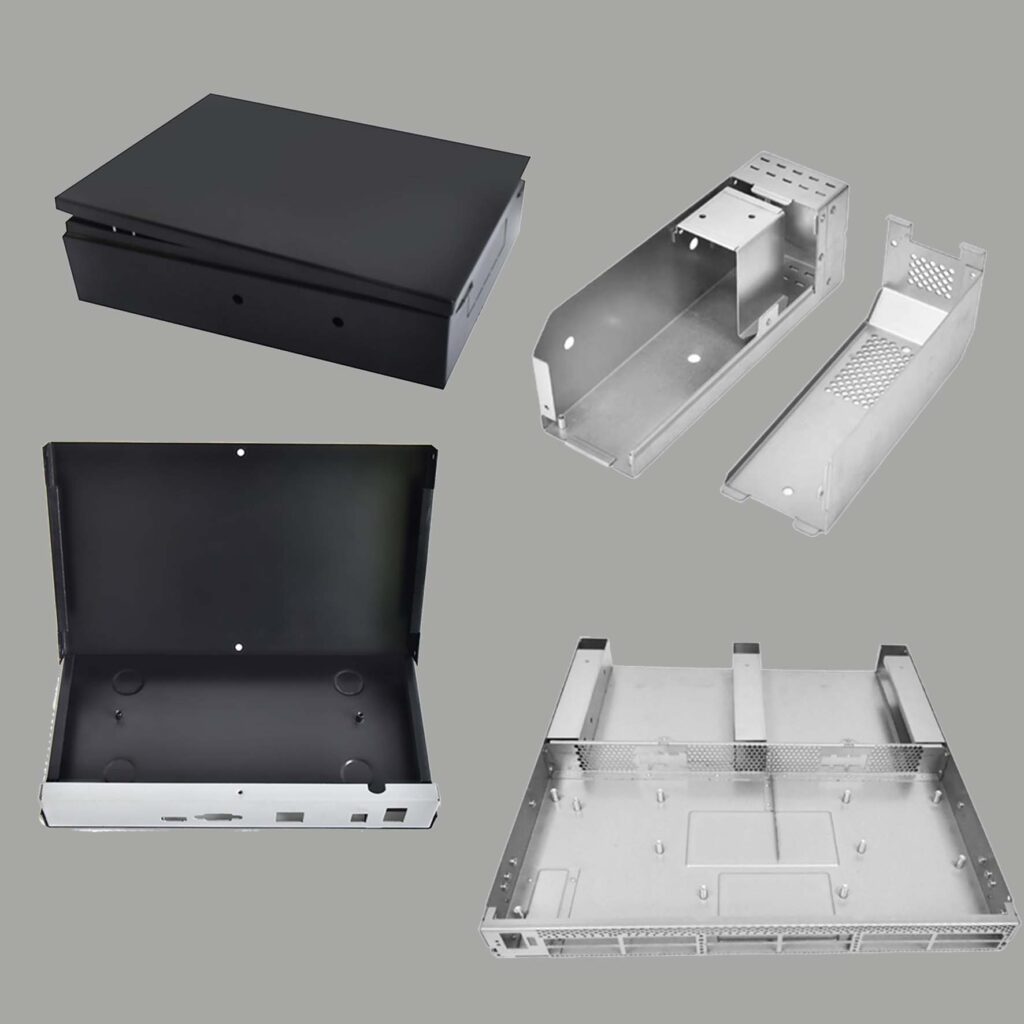

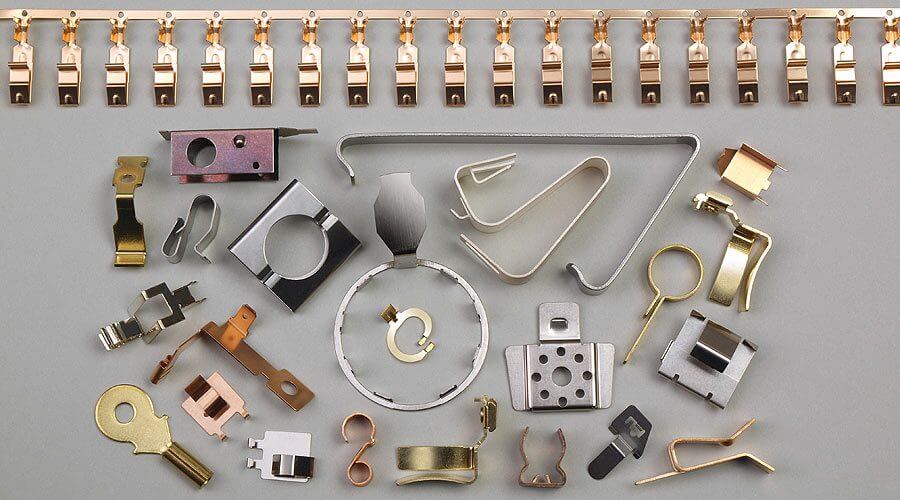

Metal Fabrication Service

We are specializes in transforming sheet metal, tubing and other raw materials into precise, custom-engineered parts and assemblies, suitable for a wide range of industrial applications including construction, automotive, and aerospace. Utilizing cutting-edge techniques such as welding, laser cutting, water jet cutting, forming and machining, we create complex structures and components that meet exacting specifications. Our experienced team works closely with clients from design to delivery, ensuring each product not only meets the required standards but also optimizes functionality and cost-efficiency.

With a focus on quality control and quick turnaround times, our comprehensive service supports both small-scale custom jobs and large-volume production runs, delivering robust solutions tailored to each client’s unique needs.

Laser Cutting

Welding

Bending

Stamping

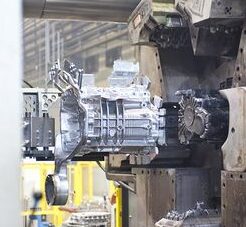

Die Casting production

Die casting is the process of shaping metal into a specific shape, known as casting. Many different non-ferrous metals can be used in die-casting processes to achieve a large number of die-casting applications. In fact, any metal part can be created using die casting technology, whether it is simple or complex. Metal components have extremely strong heat and corrosion resistance, making them very suitable for applications in many industries, including automotive, aerospace, and energy industries etc.

Sand Casting

High Pressure Casting

Low Pressure Casting

Lost Was Casting

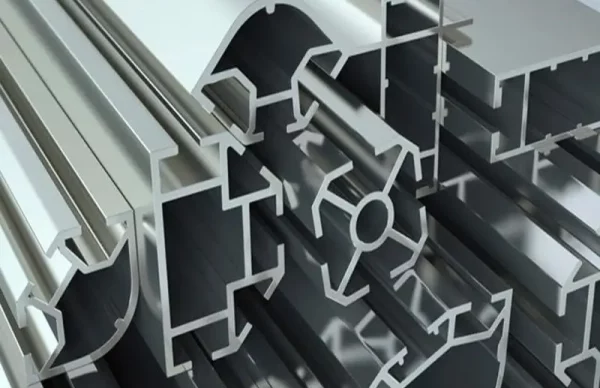

Aluminium Extrusion

Hot/ Cold Forging

Secondary operation

Although the injection moulding of plastics and LSR is the basic work of Arktech Mold, we increasingly find that secondary operation and assembly operations are required. These range from panting, printing, ultrasonic welding, laser welding, assembling products or subassemblies and and packaging to the press-fitting of bearings or inserts and the application of foam or double-sided tape. It’s all possible in our own assembly department and strategic partner.

Ultrasonic Welding

Printing & Laser

Surface Coating

Plating

Hydro Transfer Printing

Assembly

Research and development

All innovations begin with an idea. A thought, a wish, a ‘what if’ … As an expert in injection moulding and the broad range of possibilities in plastics processing, we will gladly think along with you even at the early stages of the development process. Because no matter how small or large the component is, it will always be part of a bigger picture.

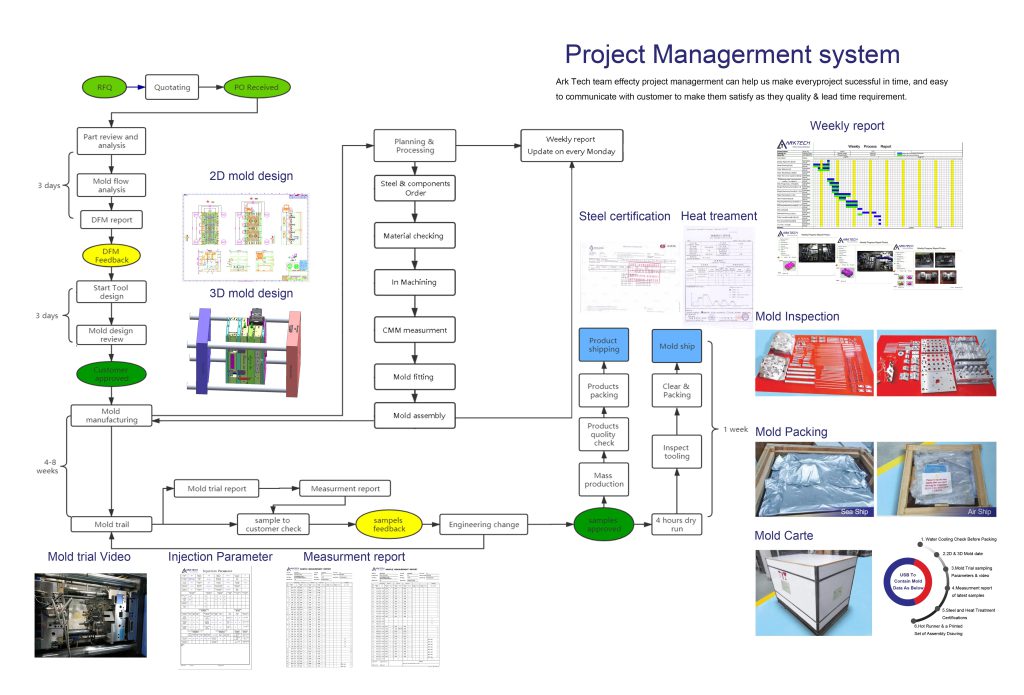

Project Managerment

The members of the project “team” include one project manager, one CNC team leader, one EDM team leader and one mold assembly team leader. Since these machining groups is the key important to control the quality and lead time. It had a projects schedule in our workshop, let everyone know the progress of each project. If the machining date is later than the plan, then the project manager will make the coordination to put the schedule within plan. By this way, we can guarantee quick and on-time delivery, which wins good testimonials from our customers.

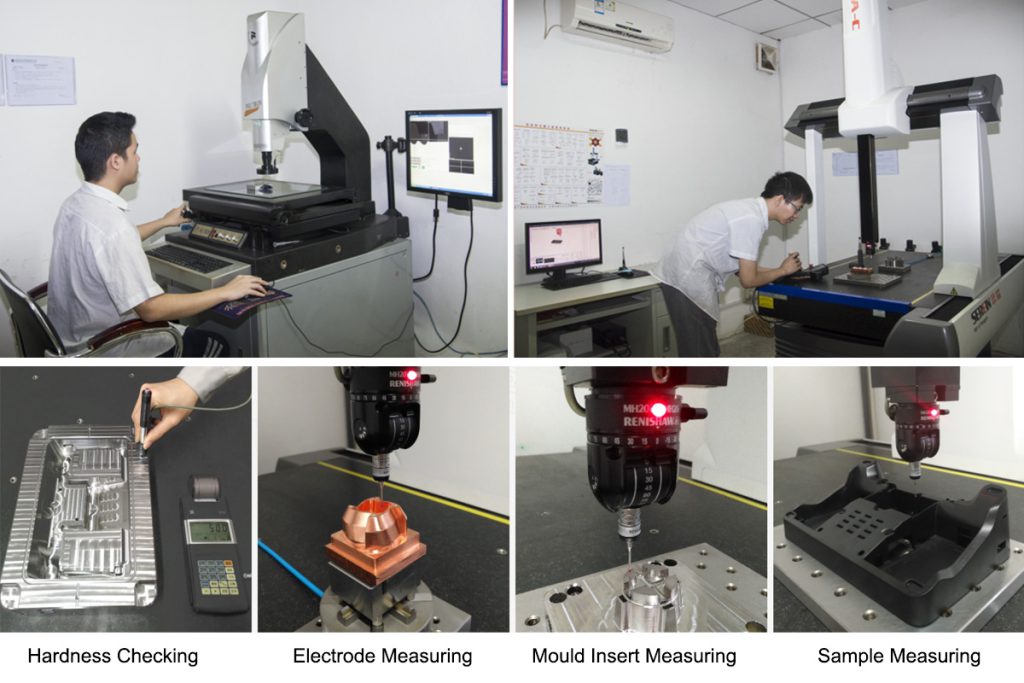

Quality Management

We regard the quality as the life of our company, in order to ensure the excellent quality of the mold. Arktech Mold is equipped with a three coordinate measuring instrument, two-dimensional projector, hardness detector, depth gauge and other high- precision measuring equipment . From mold steel hardness checking to electrodes, mold inserts, samples size measuring, we strictly control the quality, to make customers reassured.