The Group

Arktech Group. was established in 2010, mainly engaged in CNC machining, Mould making, 3D printing, Vacuum Casting, Injection molding, Sheet metal fabrication,Die casting, Surface finishing business. We have established a perfect enterprise culture with humanistic care, and enjoy Shenzhen’s convenient transportation and beautiful environment.

With extensive industry experience and Arktech’s innovative in-house manufacturing and quality supply chain, our components and moulds meet our customers’ requirements.

We focus on providing the best project advice and solutions for our customers. In Arktech Group, there are over 180+ skilled technicians and engineers in a factory of over 6000 square meters, we use the most advanced technology, including all kinds of precision equipment as well as a variety of surface finishing services

Our slogan: Make Every Project Sucessful

2010

Foundation year

+260

Group employees

+12000

Sqm of companies

+2000

Customers seved

+30

Countries shipped

+3000

Projects

www.arktechmold.com

Precision Custom Parts Manufacturer Located In China

Arktech Mold is a very professional mold design and mold maker located South of China, certified ISO2009:2015 international quality standard. We have tens of processing and testing equipment including high speed CNC machine, mirror EDM, precision grinder, lathe, milling machine, drilling machine, tapping machine, injection molding machine and three coordinate measuring machine.We started to build the complete molds since 2011, specializing in manufacturing different types of injection molds for exporting worldwide mainly North America and Europe, including:

- Conventional custom plastic molds

- Precision injection moulds

- Insert molding tools

- Unscrewing molds

- Gas assist moulds

- Insert molds

- High cavitation injection molds

- Mold making for large components

- Two Shot molds / 2K molds/ Bi-injection moulds

- Injection structural foam molds

- Special structural moulds

- Prototype molds

- Thermoset molds

- Die casting too

We are committed to provide you premium and high precision molds based on the most competitive price and fast delivery.

Our advantage

One-stop service

We offer a full spectrum of manufacturing services—including CNC machining, injection molding, sheet metal fabrication, 3D printing, compound molding, and die casting—delivering true end-to-end product development solutions.

Precision machining

Introducing the world’s advanced processing equipment, with high-precision machining and manufacturing capabilities, all prototypes and end-use parts meet strict Quality Standards and tolerance requirements.

Rapid prototyping

We let you test a variety of materials and finishes so you can make informed decisions about how to move forward with your project. We have a range of rapid prototyping processes for you to choose from.

Experienced

With more than ten years of experience in the prototype industry, a team of talented engineers can quickly solve various processing problems for you.

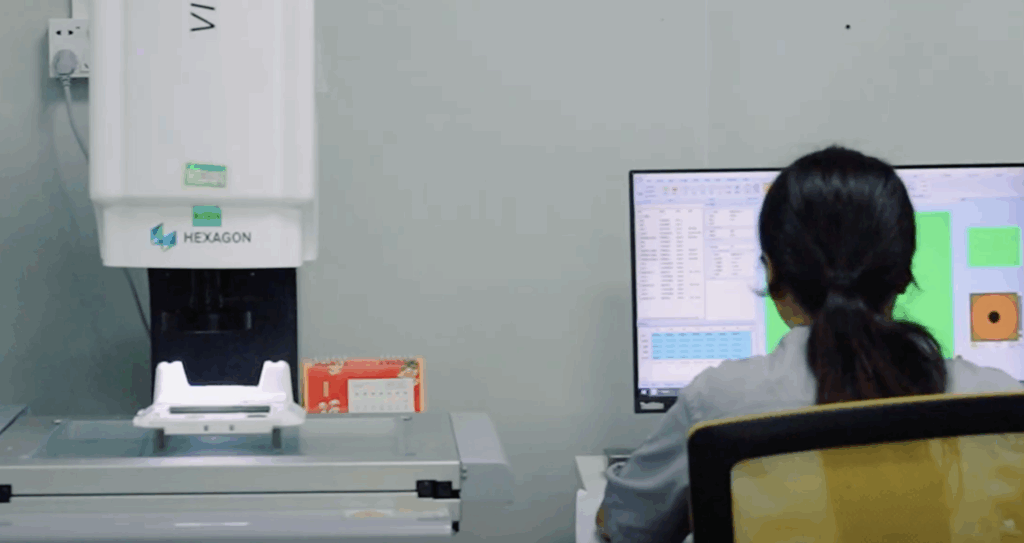

Quality Assurance

Advanced manufacturing processes, rigorous quality assurance measures, and adherence to industry standards ensure the high quality, accuracy, and durability of your parts and prototypes.

Arktech Culture

“Devotion,Teamwork and Win-win cooperation” is our constant development creed.

“Devotion,Teamwork and Win-win cooperation” is our constant development creed.

We provide reliable and professional solutions from prototype moldels to mass production. High quality mold and product quality, competitive price and timely delivery win the continued trust of our customers

Our engineering team always aims for convenient manufacturing and molding. We are concerned with every detail i be scrupulous about every processing step, to achieve better quality.

Good team cooperation spirit, interlocking for the division of labor and cooperation, maximum performance of the team. We would like to establish a seamless service with the customers. Rapid response, timely communication and perfect execution make customer satisfaction.

High

Quality

Competitive

Price

Positive

Communication

Timely

Delivery

CNC Machining Department

CNC Machining Teams

CNC Machining

CNC Turning Teams

WEDM & EDM Teams

Dimension Check

Hardness Check

3D Dimension Check

Mould Department

Designer Team

Tooling Shope

Mould Teams

High Speed CNC Maching

CNC Maching Room

QC Room

Milling Teams

Grinding Teams

Polish Teams

Plastic Injection Molding Department

Plastic Injection Molding Teams

Molding Production

Other Department

3D Printing

Die Casting

Metal Stamping

Vacuum Casting

Silicone Rubber

Electroplate

Surface Coating

Painting

Assembly Teams